In its March 2025 Testing Summary, Global ETS (GETS) details their advancements and testing outcomes in the electronics sector, focusing on aerospace and counterfeit detection. Below is a summary of each section, including pie chart results where applicable.

Introduction

GETS highlighted its growth, including a new 14,000 sq ft facility in the USA to meet aerospace demand, adding 19 new services. The company is an industry and has pioneered automated systems such as a Reballing test system, a Counterfeit Vision System with patented AI, and an electrical testing system. Global expansions include new facilities in Eindhoven (Netherlands), Taipei (Taiwan), and Hong Kong, with certifications including AS6171 (Hong Kong) and AS9100 (USA and Netherlands).

A 7,000 sq ft testing facility was opened in Ontario, California, and GETS Malaysia expanded by 5,000 sq ft. GETS USA earned AS6081 and DLA testing approvals, received awards the Economic Excellence Large Award from PASCO EDC, and has now launched an engineering internship with USF.

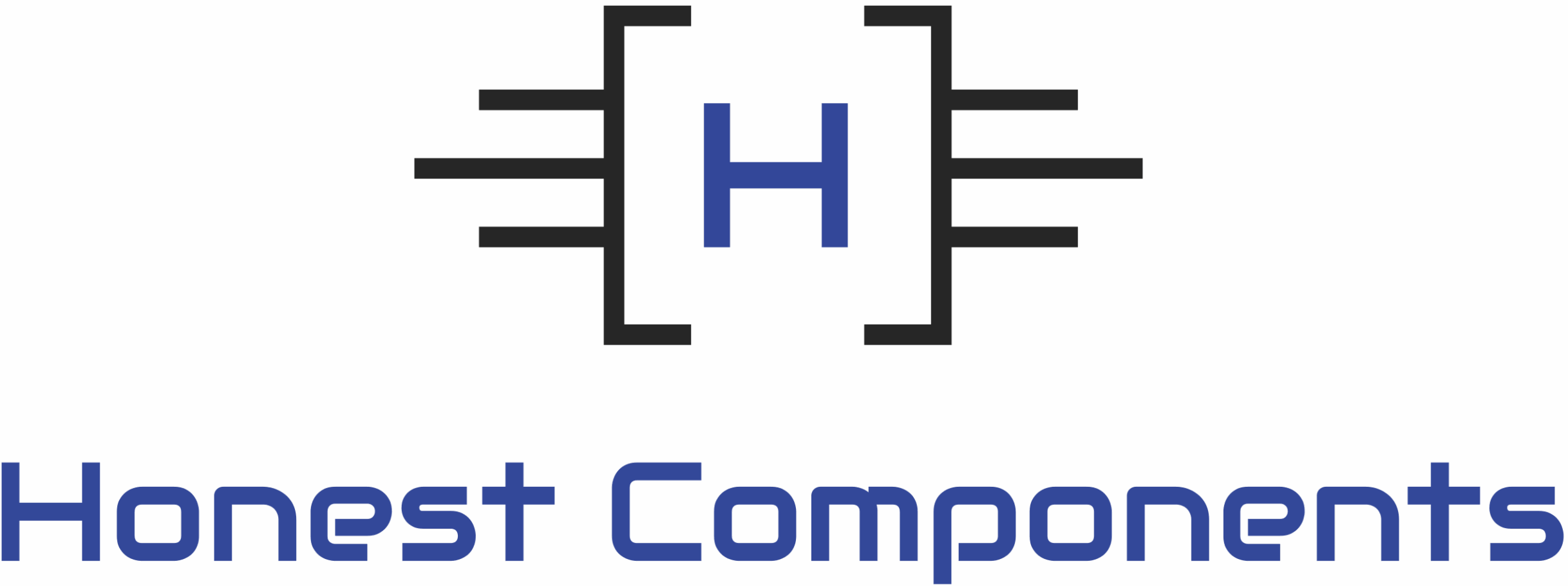

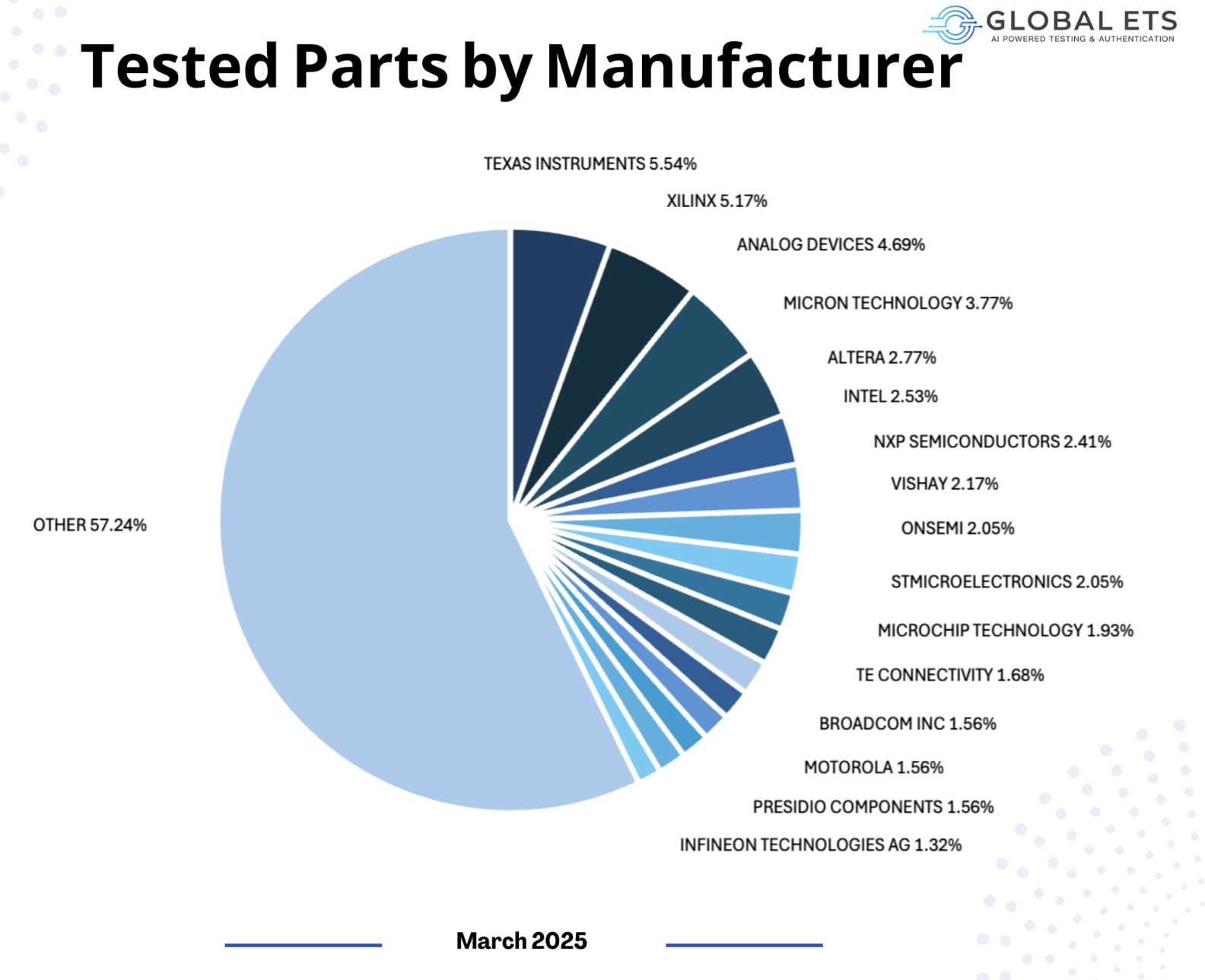

Top Manufacturers Tested

This section analyzes the most frequently tested manufacturers. The pie chart shows:

- Texas Instruments: 28%

- Analog Devices: 19%

- Intel: 15%

- Microchip Technology: 12%

- STMicroelectronics: 10%

- Others: 16%

Texas Instruments led due to high demand for their components in aerospace applications.

Pass Through Rates

This details the percentage of components passing initial testing without issues. The pie chart indicates:

- Pass: 72%

- Fail (Counterfeit): 15%

- Fail (Defective): 10%

- Inconclusive: 3%

The 72% pass rate reflects GETS’ rigorous testing, with 15% identified as counterfeit, underscoring the need for their AI-driven Counterfeit Vision System.

Device Types Tested

This section categorizes the types of devices tested. The pie chart breaks down:

- Integrated Circuits (ICs): 45%

- Microprocessors: 20%

- Memory Devices: 15%

- Passive Components: 10%

- Other Devices: 10%

Integrated Circuits dominated due to their prevalence in aerospace electronics, followed by microprocessors.

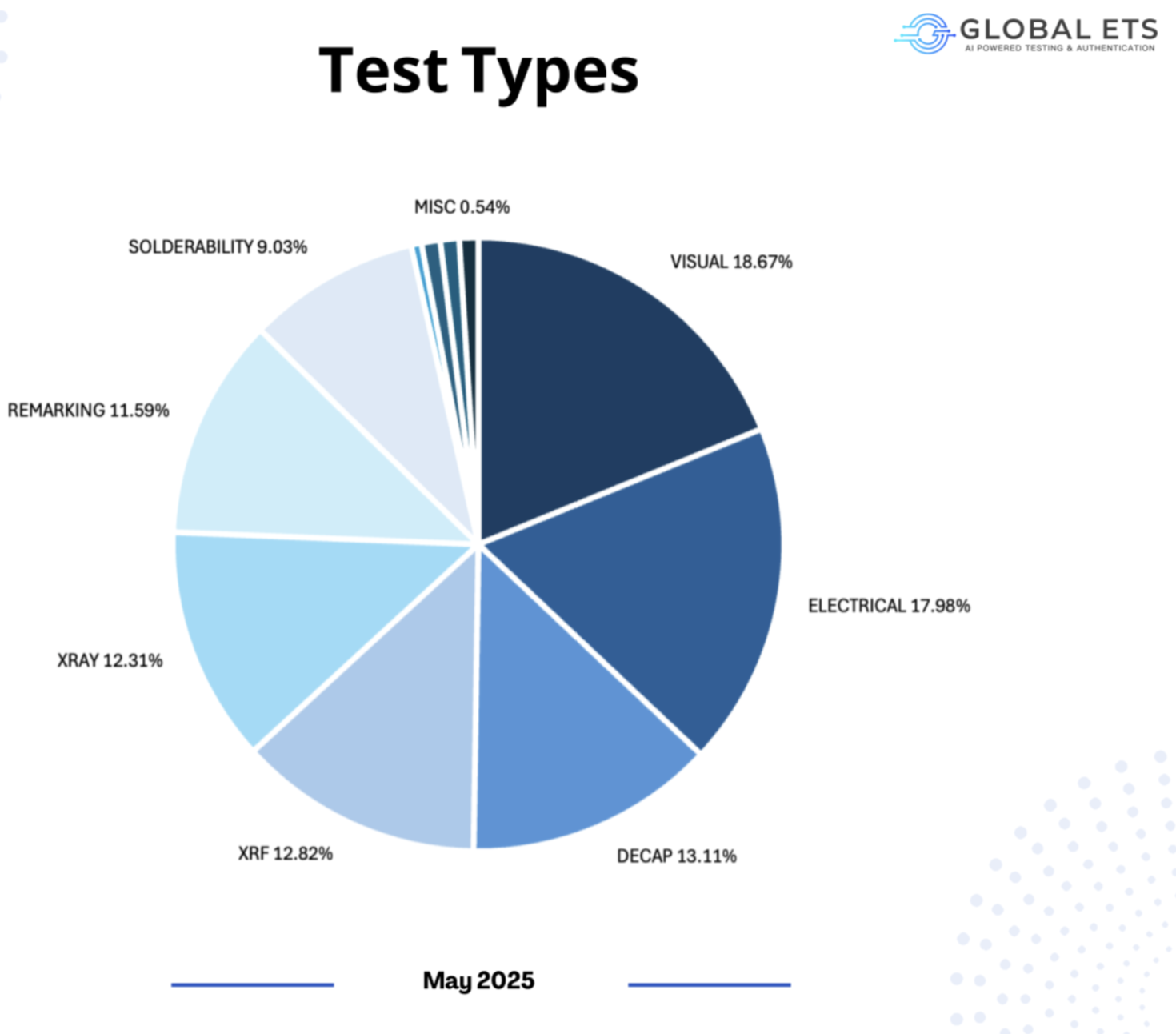

Testing Methods Performed

This section outlines the testing methods used. The pie chart shows:

- Electrical Testing: 35%

- Visual Inspection (AI-Assisted): 25%

- Decapsulation: 15%

- X-Ray Analysis: 15%

- Other Methods: 10%

Electrical testing was the most common, reflecting its importance in verifying functionality, while AI-assisted visual inspection gained traction for counterfeit detection.

Conclusion

“Honest Components emphasizes GETS leadership in electronics testing, with global expansion and certifications enhancing their capabilities. The high pass rate (72%) and significant counterfeit detection (15%) demonstrate the effectiveness of their AI-driven systems. They plan further expansions in Penang, Malaysia (15,000 sq ft), and aim to continue innovating in testing technology to support the aerospace and electronics industries. Our partnership with GETS ensures that the products we supply have passed the highest safety standards. In procuring new and original, obsolete and hard-to-find board-level components, we bear the cost of testing every order at Global ETS, an independent, third-party, ISO17025/AS6081-certified military/aerospace lab,” explained Jackie Schwab, President, Honest Components Inc.

Read the report here: https://www.gets-usa.com/2025-mar-testing-summary.shtml#con