Global Electronics Testing Services (Global ETS) has released its December 2024 electronic component testing summary, revealing crucial insights into the risks posed by counterfeit and defective components in the global supply chain.

With a failure rate of 7.89% across all tested parts, the report underscores the critical role of robust, validated testing to protect the integrity of the electronics industry. Among the companies relying on Global ETS’s comprehensive testing services is Honest Components, a leader in the distribution of high-quality, authentic electronic based-level components.

“Ensuring the authenticity and reliability of electronic components is paramount in an industry where counterfeit parts can cause significant operational and safety risks,” says Jackie Schwab, President of Honest Components. Inc. “By leveraging Global ETS’s expertise, we provide our customers with the highest level of confidence that the parts they receive have undergone rigorous, industry-leading tests. The partnership with Global ETS is a key differentiator for Honest Components, allowing us to offer products that meet the most stringent quality standards.”

“In the highly regulated world of electronics, sourcing board-level components from unrecognized suppliers poses significant risks, particularly in critical sectors such as aviation, healthcare, military and general electronics. The potential pitfalls are not merely theoretical, they can lead to catastrophic failures, regulatory penalties, and severe financial repercussions not only with the malfunction of equipment but possible litigation and fines due to regulatory non-compliance.”

The Importance of Quality Assurance

Ms Schwab explains that when dealing with essential systems, the quality of components cannot be overstated. Aircraft electronic systems, for example, are designed with safety as a top priority. “A failure due to substandard or counterfeit components can result in loss of control, jeopardizing the lives of passengers and crew. Regulatory bodies like the FAA and EASA enforce strict compliance and oversight in aviation, making it imperative for companies to source components from suppliers that demonstrate adherence to the necessary standards.

“In the medical field, the stakes are similarly high. Medical devices rely on precise electronic components to ensure accurate readings and reliable performance. Counterfeit or low-quality components can lead to misdiagnoses or equipment malfunctions, posing serious risks to patient safety. Regulatory bodies such as the FDA impose stringent requirements on medical device manufacturers, making it crucial for them to partner with certified suppliers who are certified with the necessary regulatory compliance,” Ms Schwab notes.

The Role of Certifications

To mitigate these risks, Ms Schwab emphasizes that it is essential to work with suppliers that are ISO 9001:2015 and AS9120B certified. These certifications indicate that a supplier has implemented rigorous quality management systems and adheres to industry best practices. ISO 9001:2015 focuses on consistent quality management, while AS9120B specifically pertains to aerospace supply chain management. Together, they offer a framework that enhances the likelihood of sourcing high-quality components.

The Need for Independent Testing

“Testing labs should also be certified to AS6081 test methods, including Functional Electrical Testing. This certification demonstrates that the laboratory employs rigorous testing methodologies to verify that components meet required specifications. It is crucial to ensure that the supplier’s counterfeit mitigation strategies are not only in place but also effectively followed through.

“To address potential conflicts of interest, utilizing independent third-party test labs is essential. Relying solely on the supplier’s testing capabilities can lead to complacency or, worse, the overlooking of critical quality issues. If a supplier hesitates to allow independent testing, it raises red flags about their commitment to quality and transparency,” Ms Schwab adds.

Key Findings from Global ETS December 2024 Testing Summary

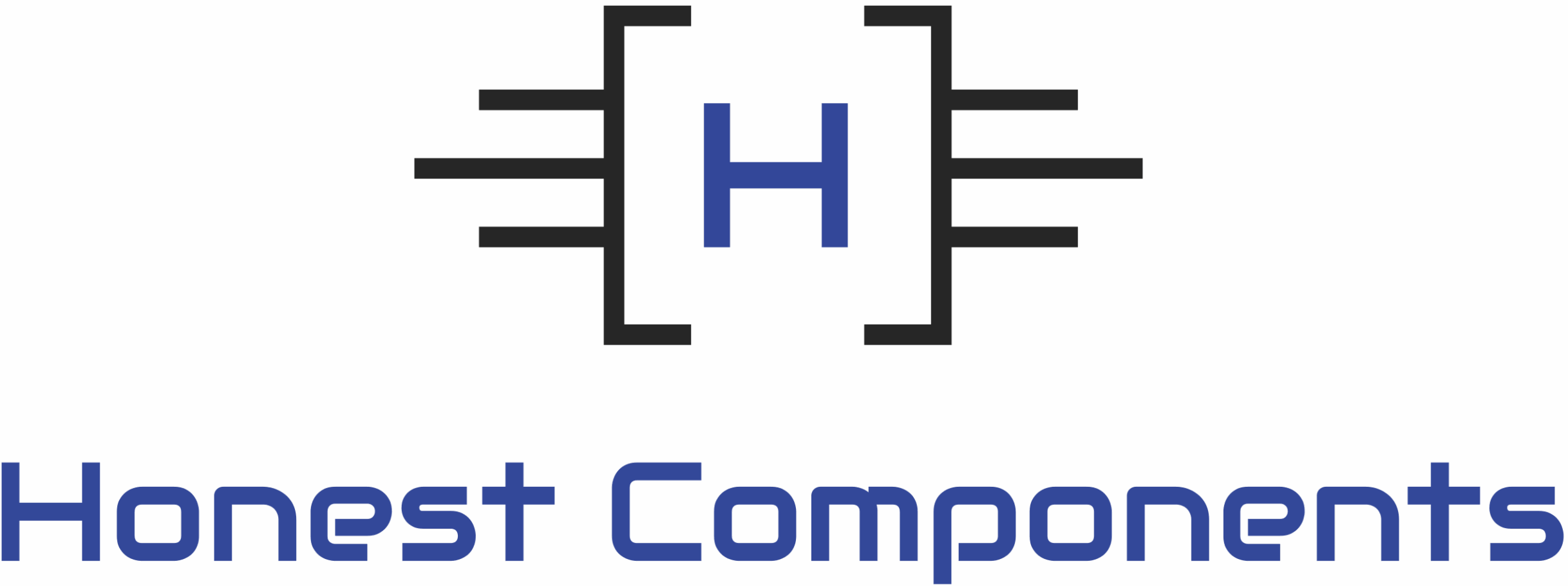

- Types of Parts Tested by Manufacturer

In December, Global ETS tested parts from top manufacturers, including Texas Instruments (4.64%), Analog Devices (4.37%), and Intel (4.37%). Interestingly, Intel overtook Xilinx for the third spot, indicating a shift in demand that could signal broader market trends. However, it is too early to determine if this is a temporary fluctuation or a long-term shift. - Pass Rate and Failures

Global ETS’s overall pass rate for components in December stood at 92.11%, a positive sign that most parts meet the rigorous standards for authenticity and performance. However, the remaining 7.89% of components that failed testing highlight the ongoing challenge of counterfeiting and manufacturing defects. This data underscores the importance of companies like Honest Components investing in thorough testing to safeguard the reliability of their products. - Parts Tested by Device Type

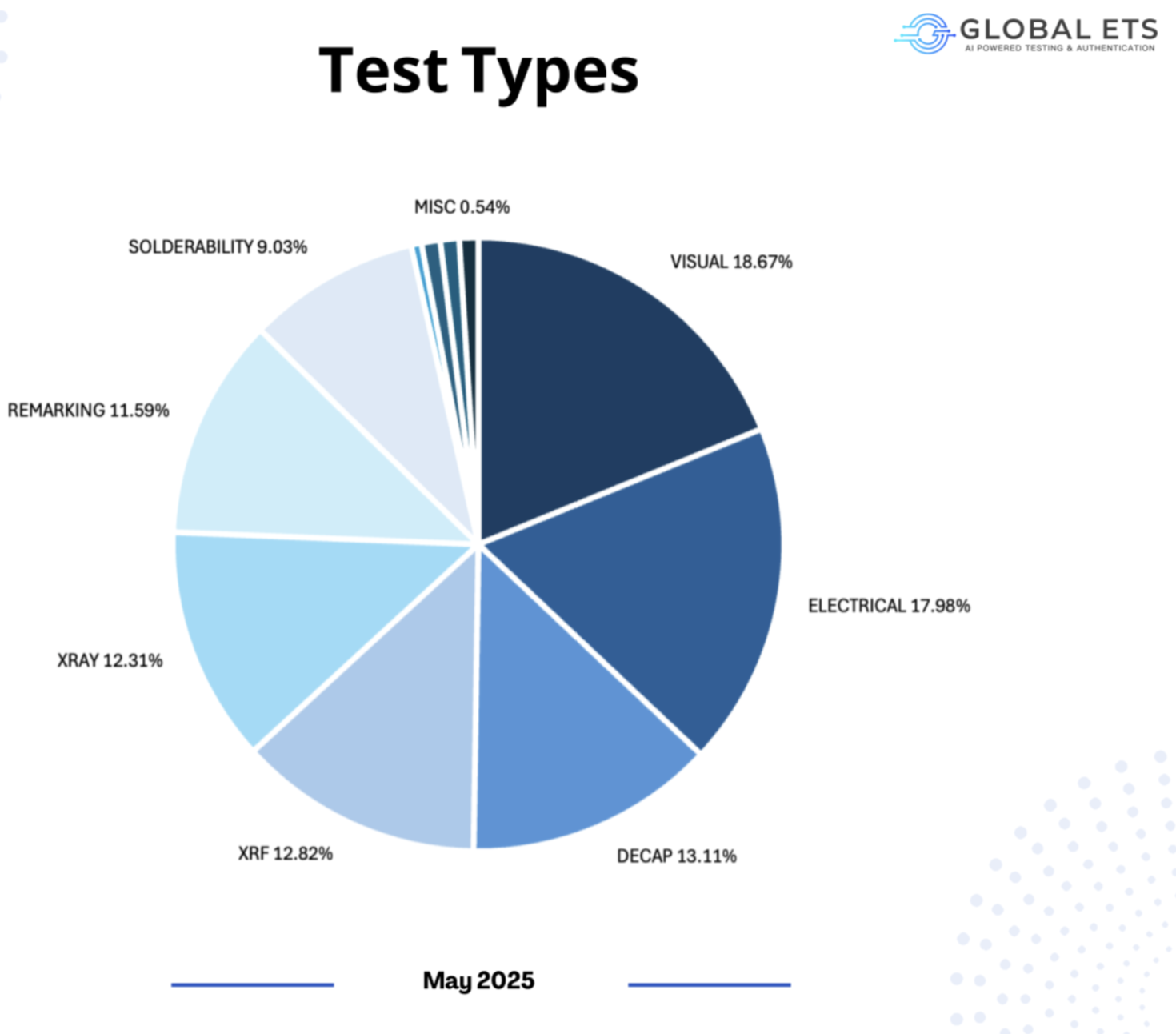

FPGA chips, amplifiers, flash memory, connectors, and switches were among the most frequently tested parts in December. These components are critical for various consumer and industrial applications. Amplifiers, for example, ensure clear audio signals in devices like headphones, while flash memory plays a crucial role in reliable data storage. Connectors and switches are essential for maintaining seamless functionality across a range of devices. - Types of Tests Performed

Global ETS uses a range of testing methods to assess the quality of components. Visual inspections (16.85%), electrical testing (16.19%), and X-ray analysis (14.29%) were the most common methods used. Other critical tests such as XRF (13.2%), decapsulation (12.18%), and remarking (10.86%) are also performed to verify the materials used in components and ensure their authenticity. XRF, in particular, works in tandem with X-ray testing to confirm that components meet expected specifications.

The Growing Need for Robust Testing in the Electronics Industry

The increasing complexity of the global electronics supply chain makes it more critical than ever to invest in comprehensive testing methods that ensure the authenticity and performance of every component. With the growing risks posed by counterfeit parts and manufacturing defects, companies like Honest Components are prioritizing rigorous testing protocols to ensure they deliver only the most reliable, high-quality electronic replacement parts and products to their customers.

“We’ve worked closely with Global ETS because they have the tools, expertise, and data to identify trends and detect issues before they reach our customers,” says Ms Schwab. “This ongoing partnership helps us deliver peace of mind to our clients and ensures that the components we sell meet the highest standards of quality and authenticity.”