A May 2025 report from Global Electronics Testing Service (Global ETS) indicates a concerning percentage of electronic component failures, signaling potential vulnerabilities in aerospace, defense, and medical supply chains.

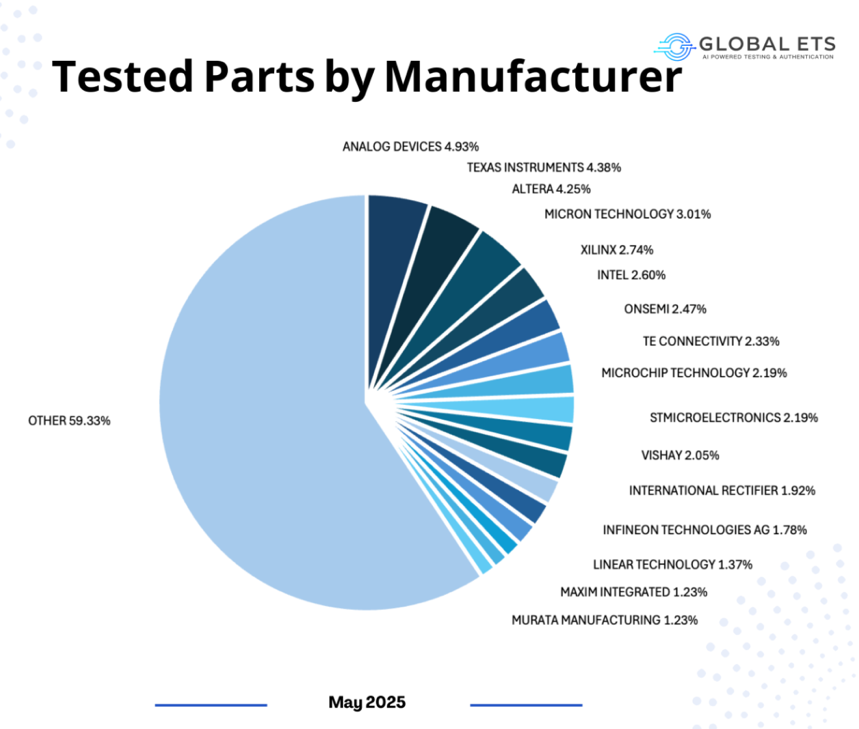

Board-level electronic component supplier Honest Components states that, based on testing of over 10,000 components, the Global ETS reports shows an overall pass rate of 93.83%, a marginal improvement from April’s 92.26%. This translates into a 6.17% failure rate, with counterfeit risks highlighted among key manufacturers like Analog Devices, Texas Instruments, Altera, Micron Technology, Intel, all above a failure rate of 2.5%.

“The tests are conducted using Global ETS’ rigorous methods, including X-ray and decapsulation. This data underscores the ongoing challenge of ensuring part authenticity as demand for End Of Life (EOL) components intensifies, says Honest Components President, Jackie Schwab.

The report breaks down testing by manufacturer, revealing concentration risks. Analog Devices topped the list at 4.93% of tested parts, a figure that reflects their prevalence in industrial controls and medical devices—sectors prone to counterfeiting. Texas Instruments followed at 4.38%, while Altera accounted for 4.25%, driven by demand for Programmable Logic Devices (PLDs).

Xilinx’s share dropped from 4.50% in April to 2.74% in May, suggesting a shift in market dynamics or reduced testing volume. These components, critical to high-stakes applications, showed vulnerabilities, with May’s 6.17% failure rate indicating that over 600 of the 10,000+ tested parts failed to meet standards, per Global ETS’ analysis.

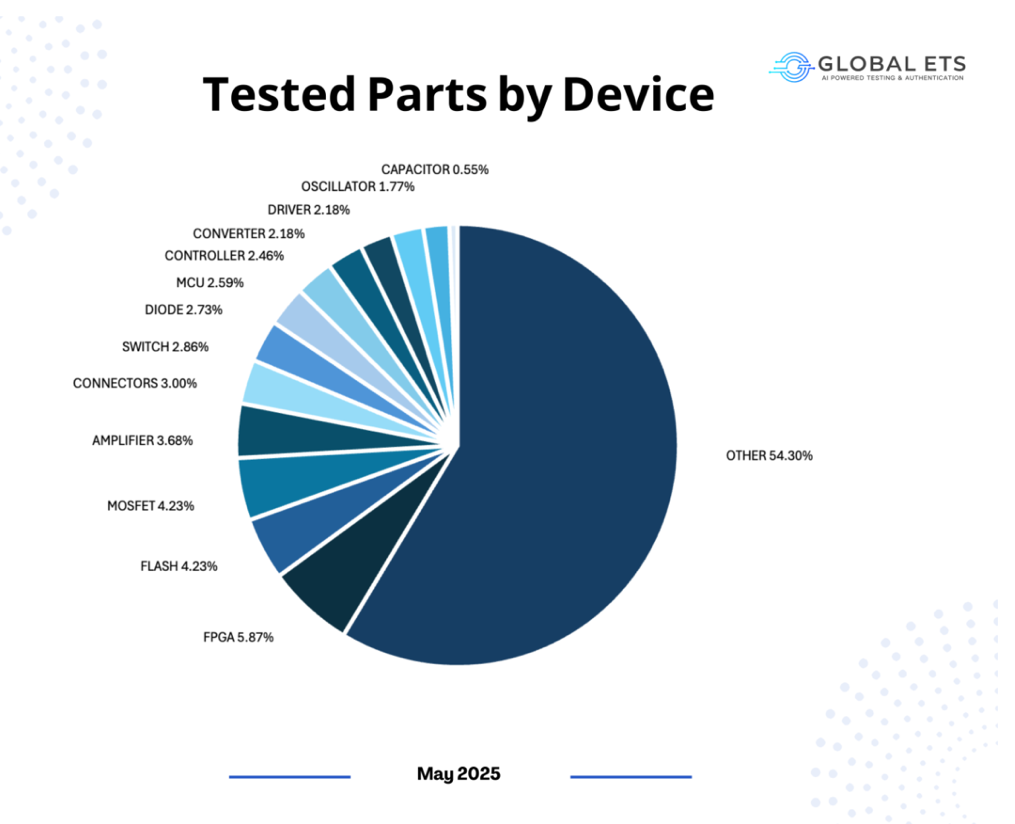

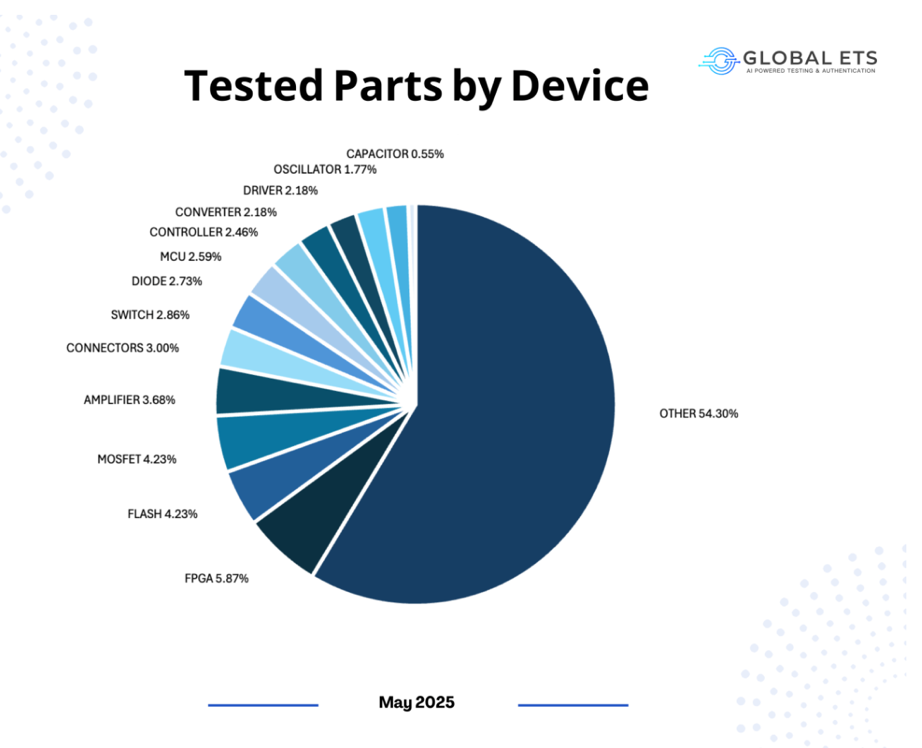

Device-type data further illuminates the issue. FPGAs, or Field-Programmable Gate Array, a semiconductor device that can be configured by the user to implement custom digital circuits, led at 5.87% of tested devices, their versatility making them a counterfeit target. This was followed by Flash Memory and MOSFETs (a Metal-Oxide-Semiconductor Field-Effect Transistor – a semiconductor device used to amplify or switch electronic signals, each at 4.23%.

Amplifiers (3.68%) and connectors (3%) rounded out the top five, highlighting ongoing concerns in storage, power management, and connectivity. The 6.17% failure rate across these categories suggests that counterfeit or degraded parts could compromise system reliability, a risk amplified by the report’s focus on EOL components.

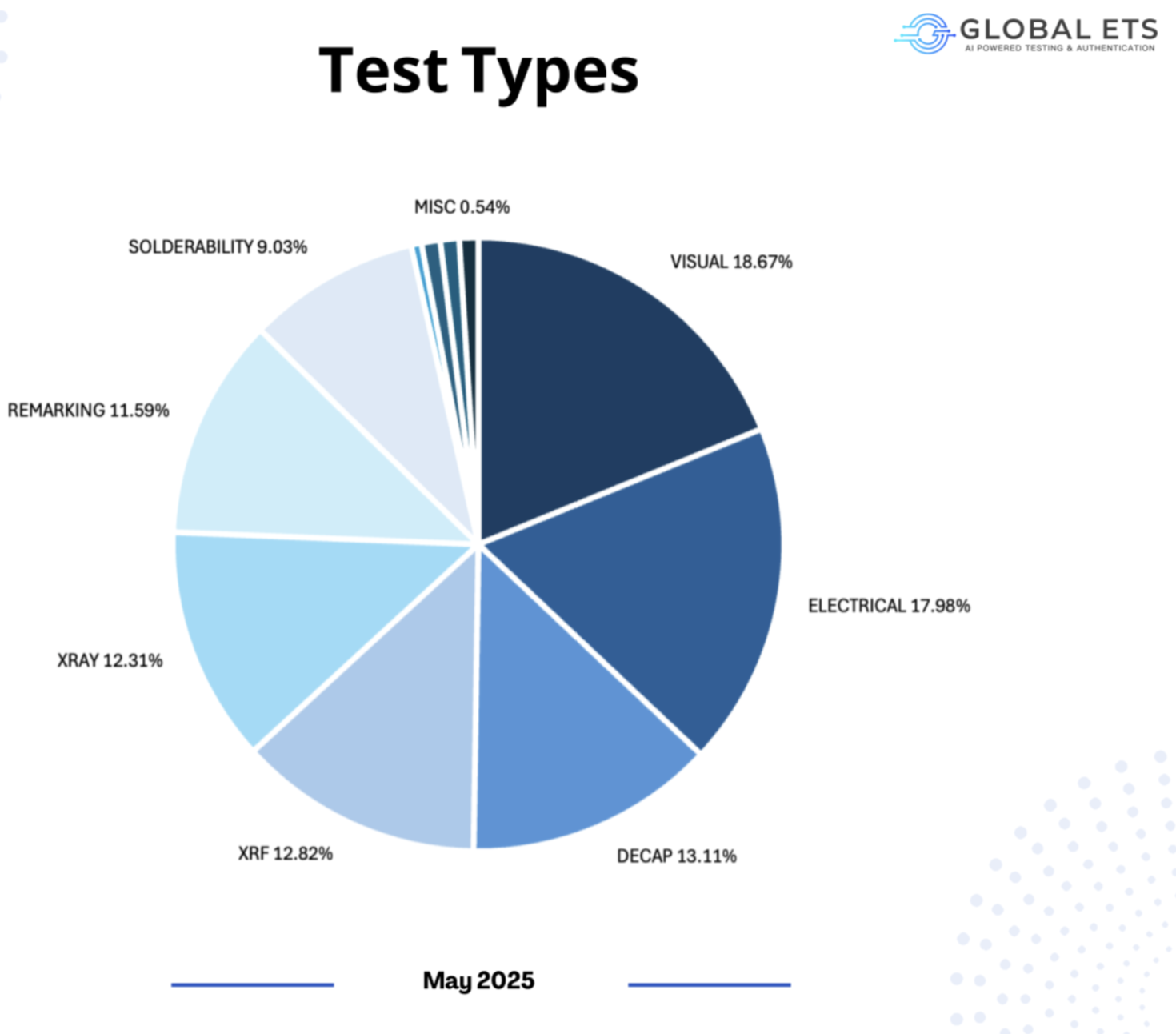

“Testing methods underscore the depth of the investigation,” Ms Schwab adds. “Visual inspection, at 18.67%, remains the primary tool for spotting suspicious markings, while electrical testing (17.98%) verified performance against specifications. Decapsulation (13.11%), XRF analysis (12.82%), and X-ray inspection (12.31%)—all part of the AS6171 standard—provided internal structural insights, identifying the 6.17% failure rate. This improvement from April’s 7.74% (100% – 92.26%) offers cautious optimism, but the persistent failure rate signals no room for complacency, especially as 40% of tested parts were EOL, based on industry trends cited in the report.”

In conclusion, the Ms Schwab notes: “The implications are significant,” Ms. Schwab notes. “A 6.17% failure rate, though relatively low, can still translate to hundreds of defective parts in high-volume orders. This poses real risk in critical sectors like aircraft navigation or medical diagnostics. The report reflects a market where counterfeit infiltration remains a threat, and failure to verify components could lead to costly recalls or safety incidents. Industry experts warn that unverified parts could lead to costly recalls or safety incidents, echoing past failures linked to substandard components.”